These aren’t the diodes you’re looking for

Posted: February 19, 2012 by ralliart12 in Technopia, ~ § Aquascape § ~Tags: blue, broken, cost, Cree, customer, damaged, diffuse, diode, fan, heat, LED, light, loose, oc, olight, optic, PAR, price, reef, repair, screw, service, sink, spoilt, value, watt, XM-L, XML, XP-G, XPG

Light Emitting Diodes (LED) has steadily became the lighting of choice for reef system owners to replace their hot & inefficient Metal Halide lamps. As I have plans to migrate to reef systems in the future, I decide to try my hand on DIY-ing a LED light set, i.e. doing-it-yourself. Upon further research, I can say the learning curve is moderately-steep, but not impossible to climb. The most tricky portions involves matching the right type & quantity of drivers with the type and quantity of LEDs one is trying to “drive”, i.e. power. Due to the varied wattage & voltage requirement & tolerance of each type of LED, i.e. maximum of 3A current tolerance of an XM-L class “bulb” versus the 1A current tolerance of an XP-E class bulb, coupled with their different (forward) voltage consumption when being driven at different current ratings, i.e. an XM-L class bulbs consumes 2.9V when driven at 350mA, 3.1V when driven at 1500mA, 3.35V when driven at 3000mA, you can see how the permutations increases rapidly. But still, it was quite a solid learning experience, which I have to thank the company, RapidLED, for. They responded professionally & rapidly to all my technical queries in a manner that seems sincere in ensuring I do not make any errant purchase.

There’s also the difficulty of procuring some of the components involved in making the light set. The most troublesome item is the heatsink. Of which I am unable to find a single (heat dissipation will work better with multiple fans cooling a single piece than the same number of fans cooling separate pieces of heatsinks) 24″ long aluminium heatsink in Singapore & to import it from overseas (from HeatsinkUSA) will add significantly to the DIY cost. But despite all these (costs & technical challenges), I still strive on. I discovered there were tons more information to be found in the reef forums than freshwater counterparts, e.g. proper utilization of dimmable drivers, DIY journal such as this, this, this, this, this, this, this, this, this, & this, etc.

Just when I was about to order the materials to make a LED light set of my own, I change upon a ready-made model that is competitively-priced. Mind you, previously I was looking at the Maxspect Mazarra LED light set which would have bitten SGD$1580 (for a 2-foot tank-appropriate model) out of my wallet. The model that I end up purchasing is the OCReef X Series 120w CREE™ LED Aquarium Light, which costs USD$599.99 (which costs me around SGD$767.41, sans shipping), around half the price of the Mazarra. While the X-series I purchased loses out to the Mazarra in terms of programmability, beauty of the supporting infrastructure (the light stand, the remote control user interface, etc), functionally I will say that the X-series by OC Reef is able to go almost head-to-head with the Mazarra. In addition, OC Reef’s response to my queries before & after the purchase is quite decent as well. But most importantly, the X-series uses Cree bulbs for all its 40 LEDs whereas the Mazarra has 38% of its bulbs from Cree, 50% of its blubs from Philips Luxeon Rebel, & 13% of its bulbs from SiBDI. I would say the Luxeon Rebel (& most probably the SiBDI) bulbs are quality 3W-LEDs in their own rights, but having a full Cree-based LED light set, with 8 more bulbs (the Mazarra model meant for a 2-foot tank has 2 modules with 16 bulbs per module) at half the price? I have only this to say:

Which brings me to my next pet peeve: quality of a LED. Many of you may have came across LED applications in your daily life, be it a simple torchlight, or even as lights for your fish tank (as a matter of fact, my area of residence is using LED lamps from Aztech to illuminate the stairway), but you may be alarmed by the price of my LED light set. I wish to point out that the LEDs I (as well as many reefers) am using, are not in the same league of LEDs as those more economically-priced counterparts. For example, the Aquazonic Sirius LED light set (the model meant for 2-foot tanks). It has 60 bulbs in total & only consumes 12.5watts overall. This means each bulb can only give up a maximum of 0.21watts of light energy (assuming 100% efficiency). Each of the Cree diode in my X-series, & the Mazarra, can deal out 3 solid watts of power (when cranked up to the maximum). The X-series can provide 120watts of lighting energy when it is running at maximum capacity. On a related note, that is why my Olight I1 EOS, with a single XM-L bulb, is able to (literally) outshine similarly-sized torches with more than 10 LED bulbs; it simply is using a different class of LED.

At this juncture, many will ponder how much extra I have to pay for a ready-made aquarium LED light set compared to making one by myself. Most may assume DIY is always the cheaper route, but this time round, even I was proven wrong, as the following spreadsheet demonstrates (this is as much as I can match to the unit OC Reef is offering; but of course it isn’t a 100%-match):

| Component | Quantity | Price in USD (Unit) | Price in USD (Sub-total) |

| CREE XM-L Cool White T6 LED on star | 20 | $9 | $180.00 |

| CREE XP-E Royal Blue 3W LED on star | 3 | $3.40 | $10.20 |

| CREE XP-E Blue 3W LED on star | 17 | $3.60 | $61.20 |

| CREE XM-L Lens/Optics | 20 | $1.50 | $30.00 |

| CREE XP-E Lens/Optics (>40-deg) | 20 | $1.25 | $25.00 |

| 10.000″ Wide x 24″ Long Heatsink (excluding separate shipping) | 1 | $73.57 | $73.57 |

| 120mm Vantec Stealth Fan Kit | 1 | $49 | $49.00 |

| Y-shaped Hanging Kit | 1 | $10 | $10.00 |

| Bulk Wire (Black; 1-foot) | 3 | $0.25 | $0.75 |

| Mean Well LPC-35-700 constant current driver | 2 | $16 | $32.00 |

| Mean Well LPC-60-1750 constant current driver | 2 | $16 | $32.00 |

| 3-Prong Power Cord | 2 | $3 | $6.00 |

| 10V AC Adapter | 1 | $10 | $10.00 |

| TOTAL | $519.72 |

Of course, there are some differences in the final product, i.e.:

- technically-speaking, the X-series does not come with a heatsink, but is only mounted on a fin-less metal board, which is a pathetic excuse for a heatsink. The only consolation is that the final product is housed in an anodized aluminium body that is definitely more “polished” than my initial heatsink frame-design;

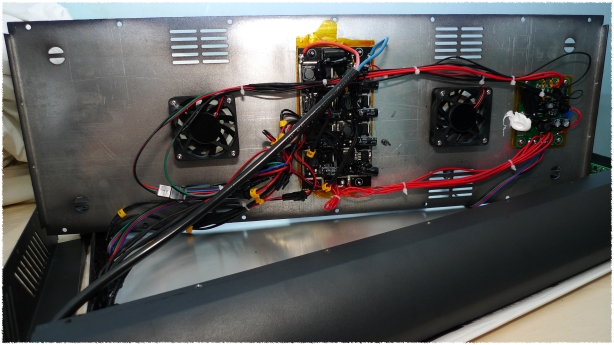

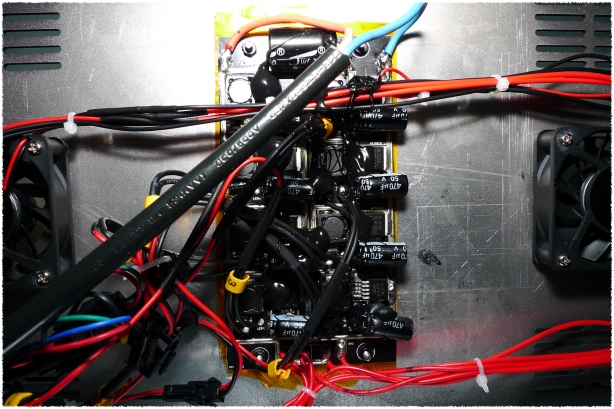

- the X-series is driven via a proper power supply box with dimming controls, as compared to the non-dimmable drivers that was in my DIY version. Furthermore, my DIY design requires 4 physical drivers, & no matter how neat I get them into a “project box”, the end-result will still be very bulky;

- the X-series come with a splash-guard, serviceable metal light stands & a remote-control. None of which were in my original DIY design.

& in the end, it still costs me “only” $599. Although I am grateful of the knowledge which I have already cumulated as part of the DIY process, but I’m sure you can see why it makes no sense for me to stick to the DIY route. In fact, the knowledge I gained enables me to be very discernible about the various attributes while shopping for a ready-made version.

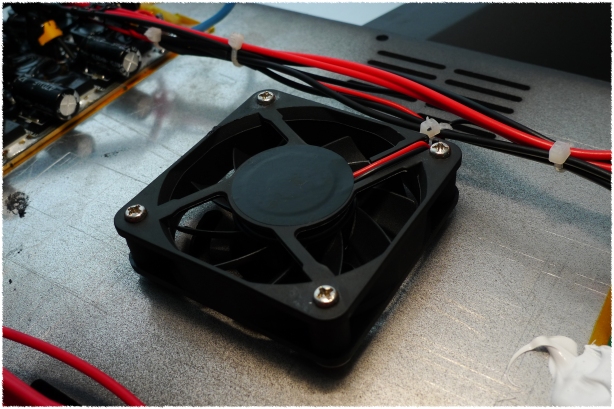

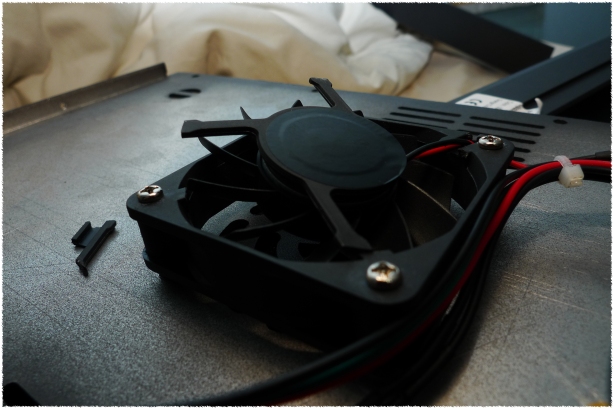

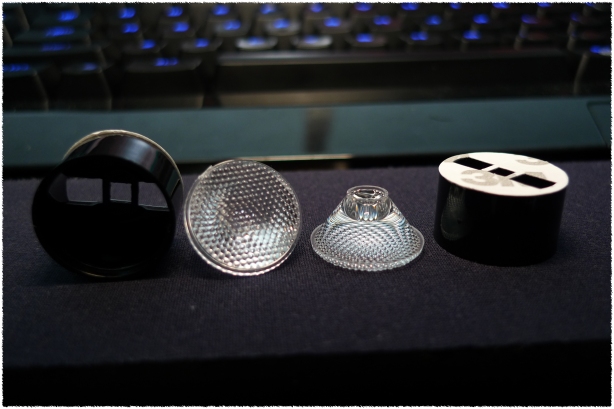

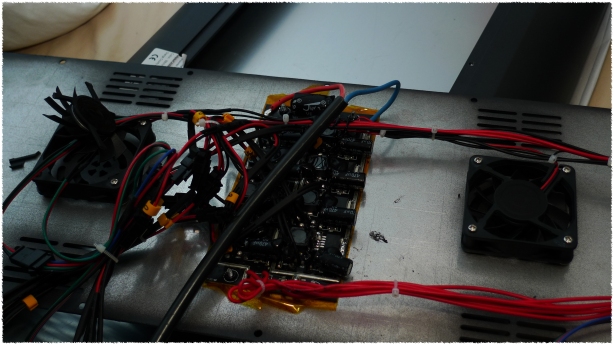

Now then, I must say the purchase, or rather, the actual unit of OC Reef’s X-series which I received, isn’t without hiccups. The unit came with a missing piece of optics (the lens used to focus the spread of an LED’s beam), & more severely, a broken fan. I was already concerned to hear what sounded like a “loose screw” upon flipping the unit around to take photos, only to realize the struts holding one of the fans in place, has been snapped. The metal “legs” that slides along the light housing for propping it up on a tank, can be much better designed. But still, all the LEDs were functional & that’s my biggest worry alleviated & only a couple of quick fixes were required to bring the product back to 100%. My after-sales inquiry regarding these defects were met with sincerity & responsiveness. & they sent me a replacement fan as well as 2 spare optics. Overall, I pretty much have nothing further to ask for.

Now I’m just waiting for an on-track tank to deploy it on…in the mean time, photos!!!

This is how one of the fans arrived in. On unpacking, one of the screws was also loose, i.e. I hear a "rustling" sound as I orientate the fixture.

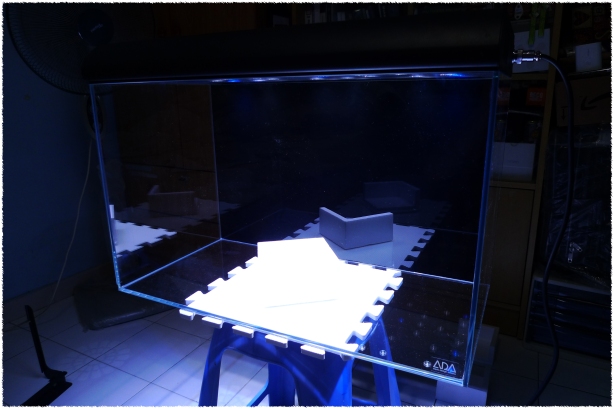

Due to the massive size of the housing, the light set can technically be used without its metal legs...

Using the fixture with its "legs" attached, showing the height clearance. The on-board mode display panel can just be seen on the left, in between 2 sets of ventilation vents.

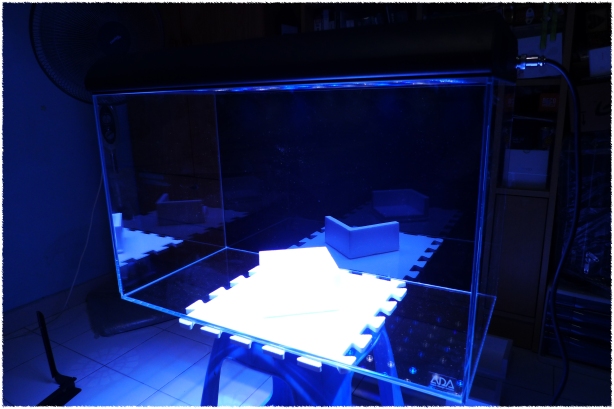

Angled view of the optics when all the diodes are activated. Notice that there are 2 sets of blue shades & 1 set of white shade.

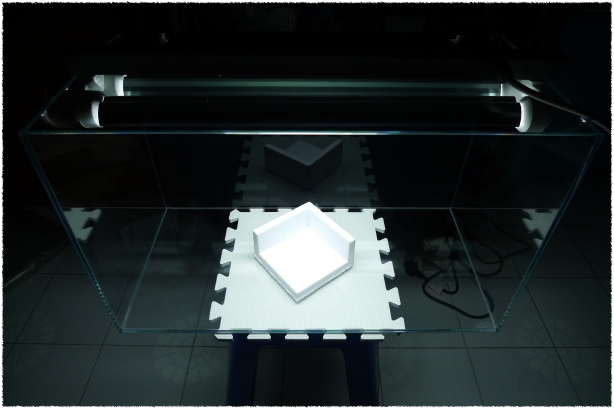

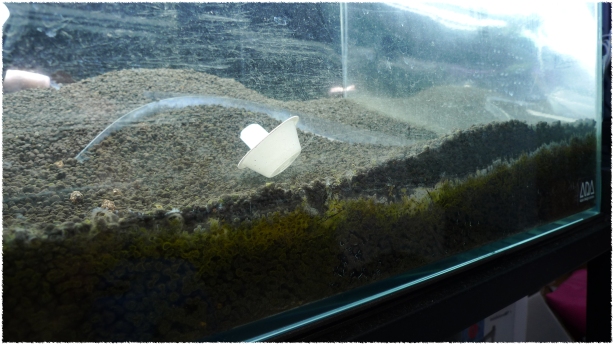

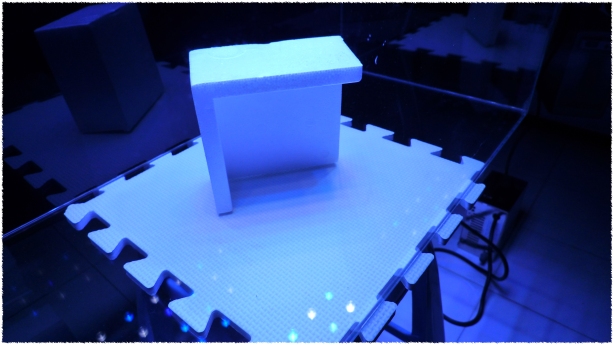

Dummy object placed in tank to demonstrate the penumbra & antumbra caused by the use of these optics. Btw, this photo is colour-corrected; it really is that blue when both shades of blue are activated.

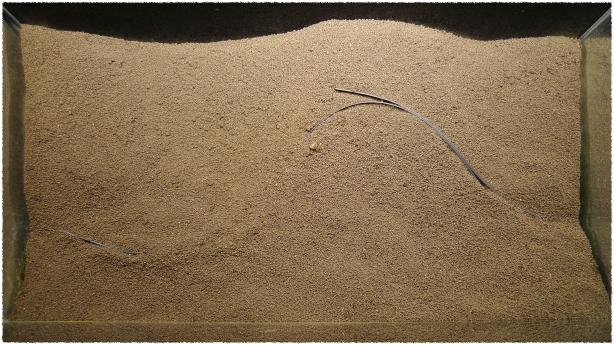

Shot of the fixture from above, showing the amount of light spilling out of the tank's cross-section.

& lastly, a video demonstration of the various illumination modes this unit can support: